In the modern pharmaceutical industry, traditional manual, semi mechanical, and semi-automatic operation methods have

gradually been replaced by automated pharmaceutical equipment due to low efficiency and high error rates, including drug

packaging production.

Drug packaging is a repetitive processing process with diverse forms and levels, large batch sizes, high speeds, programmatic and

continuous processes, and very high quality requirements. Every production step must be recorded.

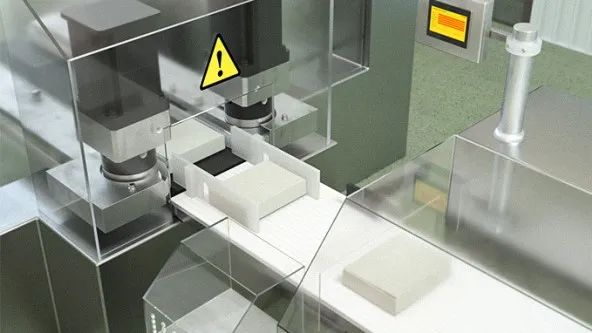

The packaging machines used in the pharmaceutical industry must inspect the materials of each packaging unit and record the

results. When a packaging unit contains multiple materials, the process becomes more complex. If enterprises want to complete

drug packaging with high quality, a highly automated, reliable, and efficient automated packaging production system is essential.

The Turck distributed control system breaks the rigid hierarchical structure through intelligent and networked technology, moving

control tasks to local devices for completion. It can identify logistics in various packaging units that frequently change, and the

verification program does not necessarily have to be integrated into production lines composed of machines from different

manufacturers.

Monitor the filling of folding boxes during the production process

Deploy Turck

The benefits of distributed control systems

Each branch node in the pharmaceutical packaging production process has a highly autonomous feature, and each node is a 'small

center'. Not only can it more effectively ensure the high-speed operation of drug packaging production, but the distributed control

solution is also very beneficial when updating tracking and recording functions: only minimal adjustments to existing systems and

controllers are needed to complete it.

User benefits

Small intervention in existing systems

Manufacturers complete factory acceptance testing to achieve rapid installation and debugging

The entire system comes from a single source

Multi protocol Ethernet for easy internationalization

Turck can provide a complete turnkey solution, including RFID radio frequency identification systems, HMI human-machine interface

operation devices and I/O modules, connectivity technology. The packaging device is equipped with an adhesive label. In the system,

the product is placed at each workstation in the packaging, and the read/write head writes the information onto the packaging unit

label. At the end of the process, compare the label information with the set values of the main controller of the distributed control

system. If the values are different, the system will activate an actuator, which will remove the corresponding device from the distributed

control system and perform manual inspection, bringing users a more flexible and secure distributed control experience.

Due to the frequent changes in the configuration of the complete set of equipment, this distributed control system includes 30

configuration options. When production changes, users can easily choose through HMI, making it flexible and versatile.

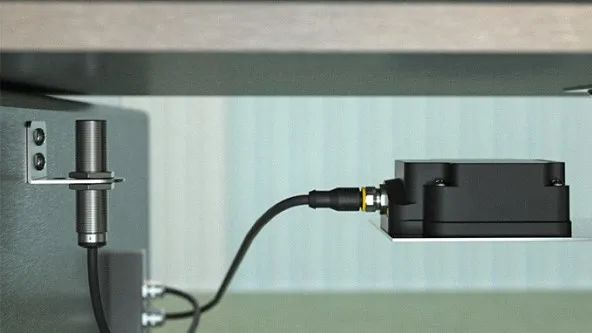

Trigger sensors and read/write heads are installed under the conveyor belt to save space

Multi protocol Ethernet used globally

This system is a BL20 CODESYS controller control system connected to HMI. The entire distributed control system can be delivered as

a turnkey solution, and factory acceptance testing (FAT) can be conducted in Turck, making it worry free and effortless.

HMI indicates errors during the packaging process and allows for changes to be made in the process workflow

In addition, the magnetic field of the read/write head in the distributed control system has no effect on the drug. Thanks to the

company's extensive experience in turnkey solutions, Turck distributed control systems have been widely applied in various industries

worldwide, providing comprehensive distributed control solutions covering the entire supply chain and production chain (including

suppliers, production, and transportation).

Postal Code: 350300

Mobile: (+86) 15606940871

Email: zhddqjt@gmail.comAddress: Building 9, Liandong U Valley Economic and Technological Innovation Center, Yangxia Industrial Zone, Fuqing City, Fujian Province,China

Follow official account